We focus on a new thermomechanical IR detection technology with micro-

We focus on a new thermomechanical IR detection technology with micro-

Aselsan (Turkey) has been the main funding resource behind this development project since 2006 and licensed the original patent by Koç University researchers. The goals of the initial project were to develop a 160×120 array with 50um pixels that are able to detect 100 mK temperature differences of targeted objects.

The first phase of the project was completed recently and the major goals were met. Currently, still images and real-

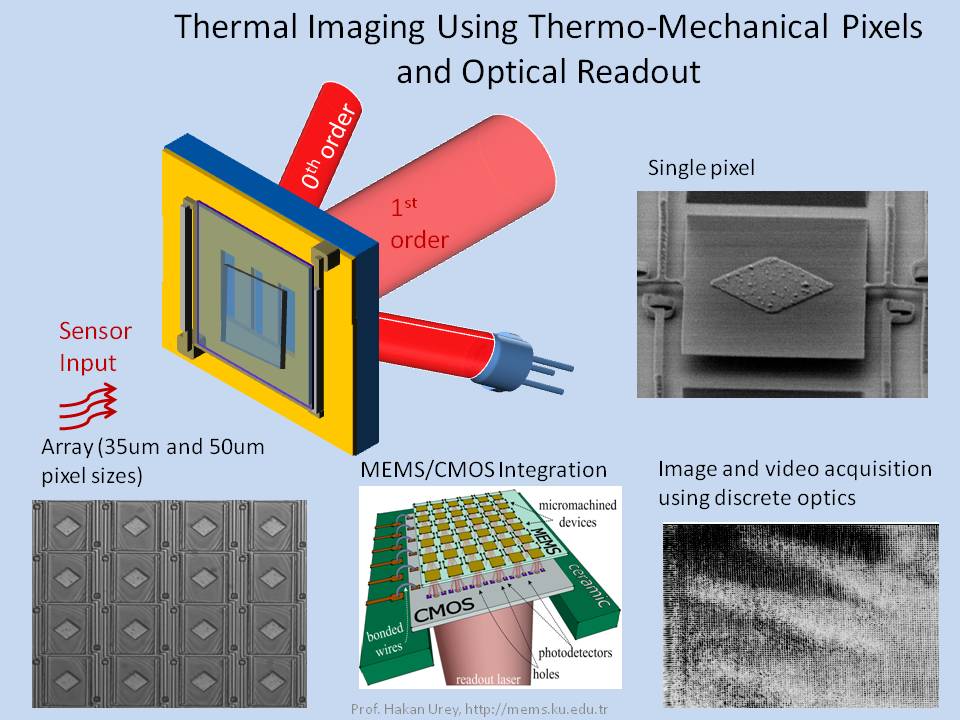

Figure 1:Image acquisition with the developed uncooled thermo-

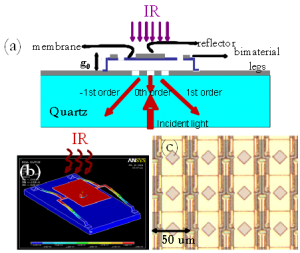

Among the various methods for sensitive displacement measurement, diffraction gratings embedded with MEMS sensors has been one of the leading methods. Atomic Force Microscopy, Grating Light Valve (GLV) display systems, MEMS microphones, bio/chemical sensors are among the applications that benefit the sensitivity advantage of diffraction gratings. The optical detection of the uncooled thermomechanical imagers, developed at OML, is also carried out using embedded diffraction gratings (Figure 2).

Figure 2 : a) Side view of an uncooled thermo-

As shown in Figure 2b, the detectors are composed of IR absorbing membranes that are connected to the substrate via bimaterial legs. Once IR energy is absorbed, the bending of the bimaterial legs create a displacement on the membrane. The movement of the membrane, and the reflector that is located on the membrane, causes the optical path difference within the gap between the sensor and the grating. This displacement can be captured by illuminating the FPA with a laser from the backside of the transparent substrate and the diffracted light can be observed using a photodetector. Sub-

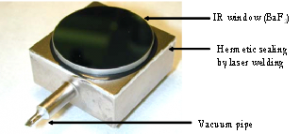

Figure 3: Vacuum-

There exist a number of advantages that differentiate uncooled thermomechanical detector arrays with optical readout from other uncooled technologies;

- The MEMS sensor array is decoupled from the readout IC (ROIC). Therefore, each part can be designed and optimized separately allowing for different wafer material and size selection for the IR sensor and ROIC.

- The IR detector array is completely passive, i.e., does not require any electrical connections to the substrate and very good thermal isolation can be achieved.

- Designs are easily scalable to small pitch and higher resolutions as it doesn’t require electrical interconnections on the detector chip.

- Microfabrication is simple, uses standard MEMS processes and requires only a 4-

mask process. - The array is immune to saturation (or sun-

blindness effect while observing high temperature targets) due to cyclic readout signal of the interferometer. - Large dynamic range can be achieved. This is possible by incorporating readout algorithms to extend the range of the optical interferometry beyond l/4 offered by the standard readout using one laser.

- Diffraction grating based readout is proven to achieve very high precision for detecting small mechanical deflections therefore theoretical NETD levels as low as ~10mK seem possible.